When, Where, and How to Use High Friction Surface Treatments (HFST) Effectively

Services: High Friction Surface Treatment

High Friction Surface Treatments (HFST) are increasingly recognized as a critical tool for enhancing roadway safety. Backed by extensive research and data, HFST is proven to reduce accidents, particularly in areas prone to skidding and crashes. This article explores the optimal time, locations, and methods for applying HFST effectively.

When to Use High Friction Surface Treatments

HFST is used to significantly improve the friction of road surfaces, making it particularly effective in areas where vehicle control is crucial. Here’s when HFST should be considered:

Accident-Prone Areas

Research by the Federal Highway Administration (FHWA) indicates that HFST is estimated to reduce wet crashes by 83 percent wet-weather crashes and total crashes by 57 percent. Locations with frequent accidents, especially those related to skidding, are prime candidates for HFST. The increased friction can substantially reduce the likelihood of vehicles losing grip, particularly under adverse weather conditions.

Case Study: I-10 at I-110 Interchange Safety Project

Background:

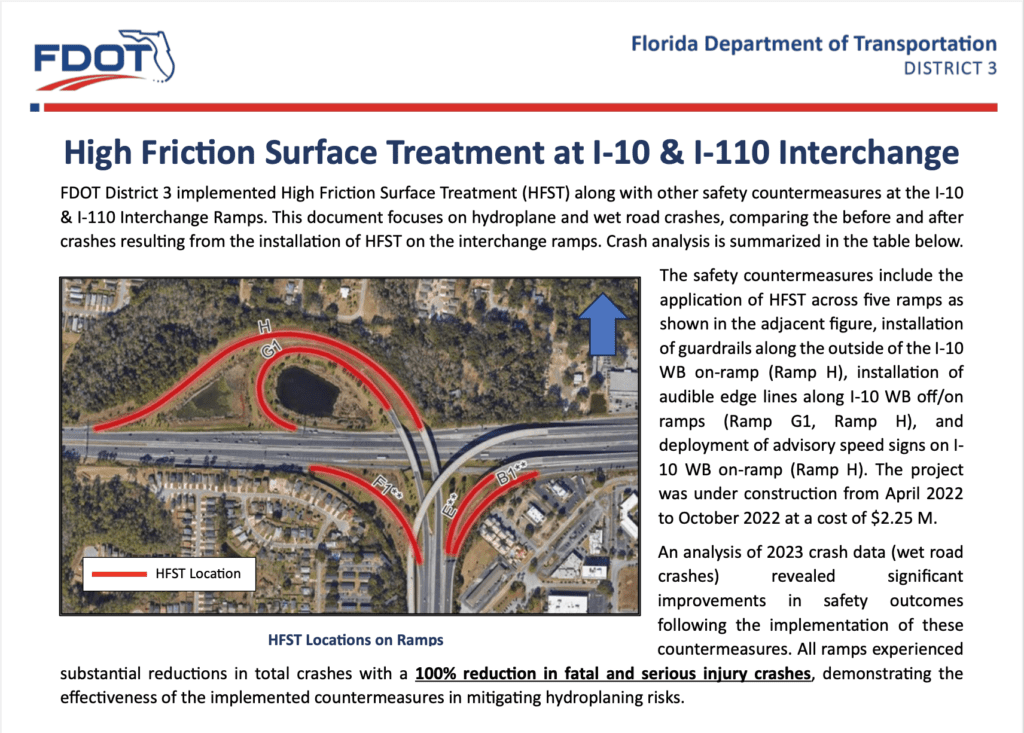

The Florida Department of Transportation (FDOT) District 3 implemented High Friction Surface Treatment (HFST) and other safety countermeasures at the I-10 and I-110 interchange ramps. This interchange had been experiencing a high rate of hydroplane and wet road crashes, posing significant safety risks to motorists. The project aimed to address these incidents by increasing road friction and improving safety features.

Project Overview:

The project was constructed between April 2022 and October 2022 at a cost of $2.25 million. HFST was applied across five ramps:

F1, E, B1, G1, and H.

Additional countermeasures included:

- Installation of guardrails along the outside of Ramp H.

- Installation of audible edge lines along Ramps G1 and H.

- Deployment of advisory speed signs on Ramp H.

Results: An analysis of the crash data from 2023 showed a significant reduction in wet road crashes post-implementation:

100% reduction in fatal and serious injury crashes across all ramps.

Ramp-specific reductions:

Ramp F1: 50% reduction in total crashes.

Ramp E: 100% reduction in total crashes.

Ramp B1: 45% reduction in total crashes.

Ramp G1: 49% reduction in total crashes.

Ramp H: 98% reduction in total crashes.

Conclusion: The I-10 & I-110 Interchange Safety Project demonstrated the effectiveness of HFST and associated safety measures in reducing hydroplane-related crashes. The substantial decrease in both total crashes and severe incidents highlights the success of FDOT District 3’s active approach to enhancing roadway safety through targeted interventions.

During Road Maintenance:

The FHWA’s research supports the use of HFST during road rehabilitation as a preventive measure. When integrated into road maintenance programs, HFST not only enhances immediate safety but also extends the service life of the road surface by preventing early deterioration caused by skidding-related damage.

Proactive Safety Measures:

HFST can be applied proactively in areas where traffic volume is expected to increase or where road conditions are likely to deteriorate due to environmental factors. According to the FHWA, applying HFST in such scenarios can prevent crashes before they occur, making it a cost-effective safety intervention.

Where to Apply High Friction Surface Treatments

The effectiveness of HFST is closely tied to its application in the right locations. Here are the ideal spots for HFST application:

Sharp Curves and Intersections:

According to the FHWA, horizontal curves account for about 25% of highway fatalities, despite comprising only 5% of the total road miles. Applying HFST to sharp curves and intersections, where sudden changes in vehicle speed and direction are common, can significantly reduce crash rates by improving vehicle traction.

Steep Grades:

HFST is particularly effective on steep grades, where loss of vehicle control due to reduced friction is a significant concern. Studies have shown that HFST can reduce crashes on grades by 20-40%, depending on the severity and traffic volume of the location.

Bridges and Overpasses:

Bridges and overpasses often experience different environmental conditions than surrounding roadways, such as increased moisture or freeze-thaw cycles, which can lead to variable friction. HFST helps maintain consistent friction levels, which is crucial for preventing skidding accidents in these areas.

Pedestrian Crossings and School Zones:

The FHWA highlights that HFST can enhance pedestrian safety in high-traffic areas, such as school zones and pedestrian crossings, by improving vehicle stopping distances and control. This treatment is especially effective in reducing accidents in urban settings, where pedestrians are at higher risk.

Highways

HFST can prevent skid resistance by adding grip to the road surface, improving vehicle traction and reducing accidents caused by high speeds in adverse weather.

Junctions

Where vehicles often slow down and accelerate, HFST is crucial to reduce the risk of rear-end and side collisions.

Vehicles navigating horizontal curves may require greater lateral friction compared to those on straight road sections, and vehicles at intersections demand higher longitudinal friction. Consequently, these areas may require pavement with enhanced frictional properties.

Pedestrian crossings

HFST increases skid resistance, which helps vehicles stop in time to allow for pedestrians and other vulnerable road users to cross the street safely.

Traffic calm zones

Residential areas, school zones and play streets can be busy, requiring vehicles to stop unexpectedly. HFST increases skid resistance to ensure that vehicles can travel in a controlled manner, minimising risk of accidents in these areas.

Application process

Proper high-friction surface treatment application is crucial for safety and longevity.

First, the existing road surface is cleaned to remove debris and contaminants, ensuring optimal adhesion.

The binder is then applied to the road surface, followed by the aggregate. Specialist equipment is used to ensure the aggregate is applied in a uniform layer before the binder cures.

Once the HFST has been applied it then takes several hours for the curing process during which time the road would remain closed to traffic.

High friction surface treatment is a proven method for enhancing road safety by reducing skid-related accidents and improving vehicle control. By investing in HFS, road authorities can ensure safer travel for all road users.

How to Apply High Friction Surface Treatments Effectively

Applying HFST is a specialized process requiring precision and expertise. This is how to apply HFST correctly:

Surface Preparation:

Proper surface preparation is crucial for the effectiveness of HFST. According to the FHWA’s guidelines, the pavement must be thoroughly cleaned and free of any debris, moisture, or oil to ensure the resin binder adheres properly. Techniques such as milling, sweeping, and air-blasting are commonly used to prepare the surface.

Application Process:

HFST involves applying a resin binder followed by a high-friction aggregate. The FHWA recommends a precise application to ensure even coverage and correct thickness. The binder secures the aggregate to the pavement, creating a rough surface that significantly enhances traction.

Curing Time:

After application, HFST requires sufficient curing time to achieve its full strength. The curing time can vary depending on the materials used and environmental conditions but typically ranges from several hours to a day. It is critical to keep traffic off the treated surface during this period to prevent premature wear or damage.

Regular Maintenance:

While HFST is durable, with an expected lifecycle of around ten years, regular maintenance is essential to ensure it continues to provide optimal friction. The FHWA suggests periodic inspections and reapplication in high-traffic areas where the aggregate may wear down over time. This maintenance ensures that the treatment remains effective and extends the life of the roadway.

Conclusion

High Friction Surface Treatments are a proven method to enhance road safety, backed by substantial research. By understanding when, where, and how to use HFST effectively, transportation departments can significantly reduce accidents, particularly in high-risk areas. Whether on sharp curves, steep grades, or busy intersections, applying HFST correctly ensures that roads remain safe for all users, even in challenging driving conditions.