I-70 / I-470 Interchange, Jackson County, Missouri

Efficient Removal and Reinstatement of High Friction Surface Treatment

You might be interested in High Friction Surface Treatments >- I-70 / I-470 Interchange, Jackson County, Missouri

- High Friction Surface Treatments

Summary

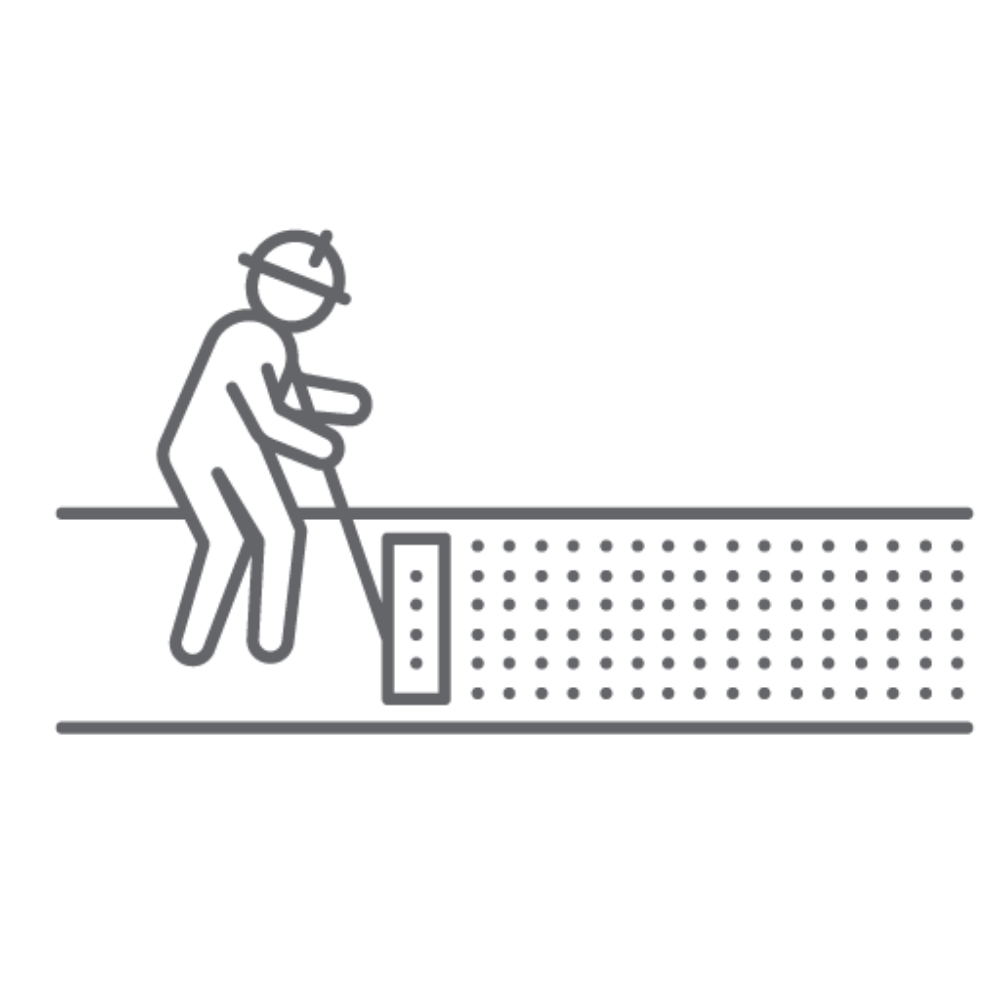

At the busy I-70/I-470 interchange in Jackson County, Missouri, WJ Surface Treatments partnered with Missouri Department of Transportation (MoDOT) to deliver a critical safety upgrade as part of the I-70 Kansas City Metro Project. While Diamond Grinding is traditionally used to smooth and prepare concrete surfaces, it can fracture the pavement and requires more plant, water, and time on site. Instead, WJ deployed our Flatliner Precision Grinding attachment, a faster, greener, and more cost-effective alternative.

The Flatliner corrects pavement irregularities without damaging the surface, using advanced pivot-point tracking, gauge-wheel levelling, and flat-tooth technology to create a smooth, uniform finish ideal for HFST application. By dry-grinding the existing HFST across 5,143 square yards, we eliminated by-products and reduced on-site disruption.

With the surface prepared efficiently, WJ installed new High Friction Surface Treatment and completed the entire project in just ten days—far ahead of the 45-day allowance. The result was a safer, more durable roadway with friction values nearly tripled, supporting MoDOT’s modernization goals and showcasing WJ’s commitment to innovation, sustainability, and high-performance delivery.

5,143yd²

Total area milled and treated with new HFST

10 Days

Actual project duration, completed well ahead of the 45 days allowed

Objectives

The project’s primary objective was to increase roadway safety by boosting friction levels on high-speed on- and off-ramps. HFST was the specified solution because it creates a textured, skid-resistant surface that reduces accidents, particularly in wet or challenging driving conditions. For HFST to perform to its full potential, however, proper surface preparation is essential.

WJ set out to remove the old HFST and contaminants, level irregularities, and create a clean textured base to maximize adhesion and longevity. Just as importantly, we aimed to deliver the project quickly and efficiently to minimize disruption to one of the busiest junctions in the Kansas City metropolitan area.

As an approved prime contractor in Missouri with deep expertise in HFST application, WJ was uniquely positioned to bring the right equipment, the right knowledge, and the right people to achieve these goals.

Challenges

Although MoDOT allowed 45 days for completion, the regional significance of the interchange meant time was critical. Traffic volumes and safety concerns required that disruption be minimized, and the ramps returned to service quickly.

Surface preparation posed a technical challenge: the existing HFST had to be fully removed with precision to ensure the new treatment bonded correctly. Any irregularities or residual contamination could have compromised the life and performance of the new HFST.

This was also the first project where WJ deployed the Flatliner Precision Grinding attachment on a state-contract job, so its real-world capability to deliver precision depth control, full-surface coverage, and dry milling without slurry had to be proven at scale.

Finally, the logistics of treating over 5,000 square yards within a compressed timeframe demanded careful planning and execution.

Results

The project was delivered successfully and well ahead of schedule, with both the milling and HFST installation completed across 5,143 square yards in just ten days. This represented less than a quarter of the 45 days originally allocated, demonstrating WJ’s ability to work with speed as well as precision. The efficiency gains were further underlined during milling operations, where 615 square yards were completed in approximately one hour, requiring only three passes at a width of 48 inches each.

The debut of the Flatliner Precision Grinding attachment was instrumental in this outcome, enabling WJ to self-perform milling with accuracy and consistency while eliminating the need for subcontractors. Its precision depth control smoothed bumps and irregularities and created a clean, textured base that improved adhesion of the new HFST. By preparing the surface properly, we ensured that the treatment would deliver maximum performance and long-term durability.

The installation of new HFST then increased friction values nearly threefold, significantly reducing the risk of skidding and accidents on the ramps. HFST’s proven benefits improved driver safety, reliable performance in wet conditions, and long-lasting durability were fully realized thanks to this combination of advanced equipment, careful preparation, and expert installation. Completing the project ahead of schedule with such efficiency not only minimized disruption to drivers but also reinforced WJ’s position as the contractor of choice for high-value, safety-critical infrastructure improvements.